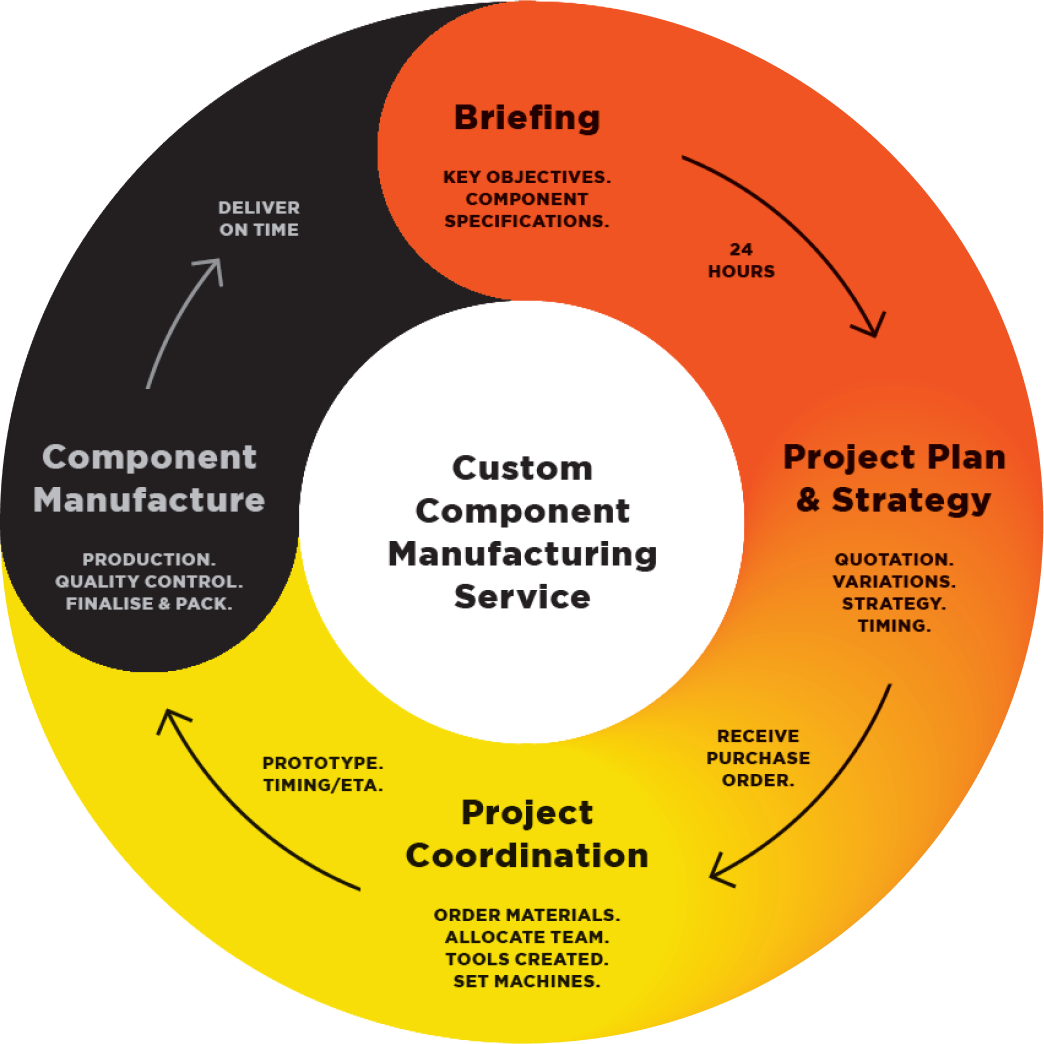

WASCA five-stage manufacturing process

If we don’t stock it, we’ll create it. Here’s how.

Stage 1: Free Consultation

Speak with our engineers directly so that we can understand your problem, and you can determine if WASCA the best speciality component manufacturing solution.

Stage 2: Briefing

Our experts will get to know your component requirements and specifications. An in-person or phone meeting will determine key objectives, timing, quantity, material requirements and dimensions.

Stage 3: Project Plan and Strategy

Here we outline the materials required, finishes if any and even target pricing. You will receive a: project quotation with cost variations and a timeline.

Stage 4: Project Coordination and Prototype

Now, we’re ready to order your materials, build tooling if required and set our machines. You will receive your: order acknowledgement and a delivery estimate.

Stage 5: Component Manufacture

During production, your order is closely monitored for quality control through our ERP system. Once we finalise manufacturing, your part is securely packed and delivered on time.